Honored to be selected as brewery equipment partner

True North Ale Company, located in Ipswich Massachusetts are proud to produce their beers on two DME systems – a 30-barrel production brewhouse and a 5-barrel pilot brewhouse complemented with 120 bbl, 60 bbl, 30 bbl, and 10 bbl fermentation and conditioning vessels.

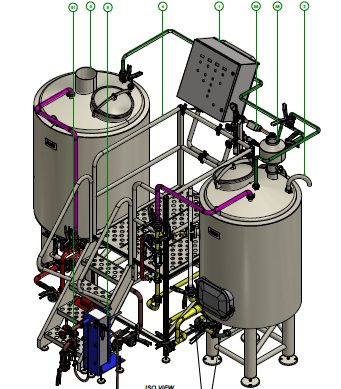

The 30 bbl, 4-vessel brewhouse was configured in close collaboration with owners Gary and Jake and was customized to fit their brewing needs; a mash mixer for thorough mixing of the mash as well as utilization of the traditional process of decoction, a lauter tun designed to maximize process efficiency, a boil kettle with an external wort boiler that allows a gentle boil while also volatilizing unwanted aromatics, and a whirlpool to separate the boiled beer from high hop loads when brewing there their IPAs.

The 30 bbl system is their lifeblood, while the 5 bbl pilot brewhouse allows them to be creative and to research and develop new one-off beers on a small scale, utilizing their Taproom customers to experiment with their emerging brews and provide feedback as they progress into the core brand lineup.

For DME, True North Ales was one of those customers that knew what they wanted, and we were honored that they selected us to be their brewery equipment partner. Our proven engineered designs, project management process and ultimately the commissioning of the system lead to a very satisfied long-term customer.